Line Notes: When a Routine Day Isn’t Routine

I honestly don’t remember the last time I sat down to write one of these. It’s been a while. Flying has settled into a steady rhythm over the past couple of months, and I’m now well past the 500-hour mark in the right seat. Most days feel routine in a good way—set the plane up, brief, fly, repeat. But every so often, a day comes along that reminds you how quickly “routine” can turn into something else entirely.

Today was one of those days.

It started out completely normal. We flew from Norfolk to JFK without issue. The next leg also went smoothly, and I was pilot flying into Nashville. Good landing, on time, nothing out of the ordinary. We were supposed to take that same airplane back to JFK after a relatively short sit—about 45 minutes, which turned into closer to an hour since we arrived early.

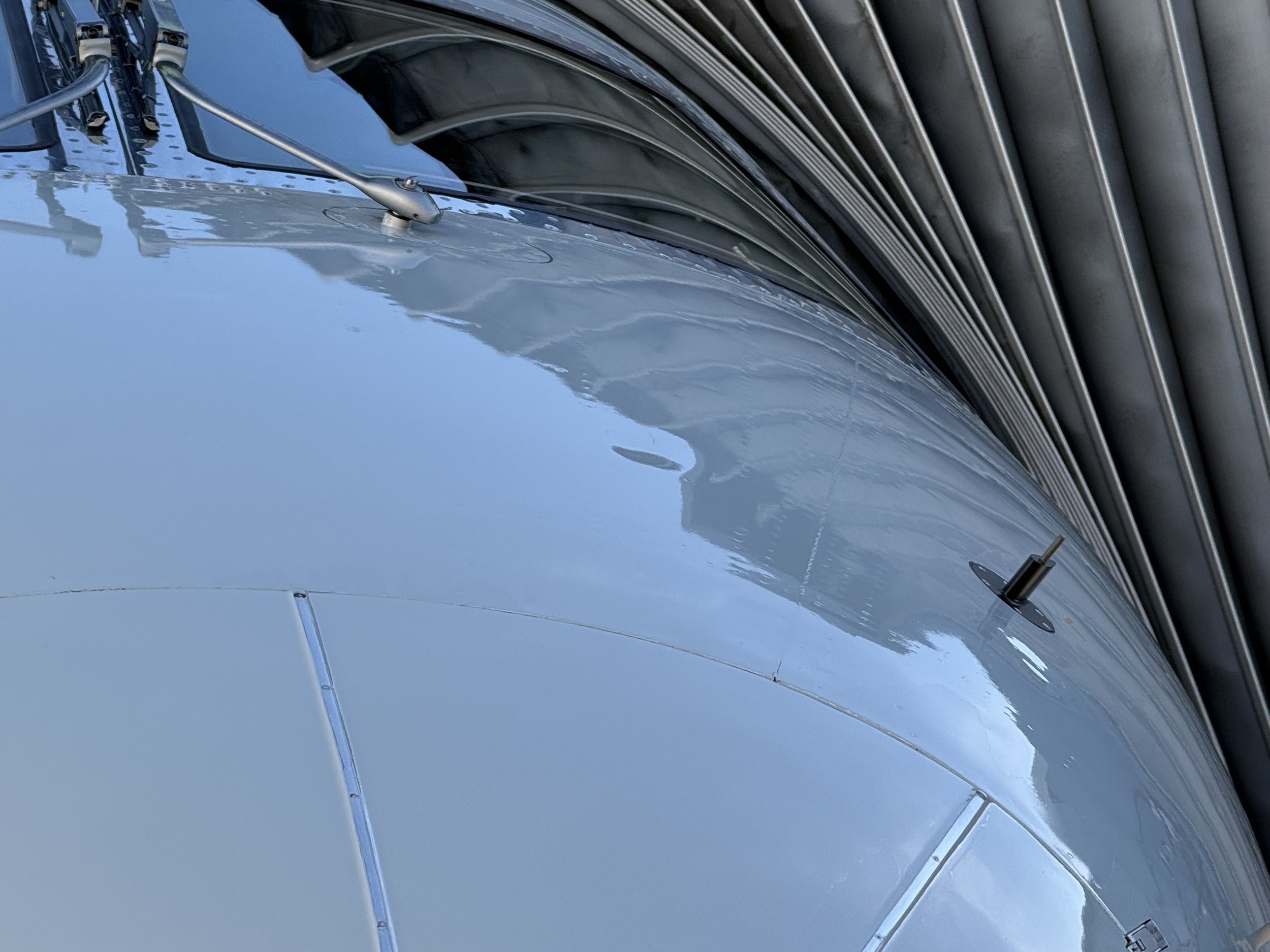

During the post-flight walk-around in Nashville, I noticed something that immediately didn’t sit right with me: a dent on the left side of the nose, right next to the icing detector probe. It wasn’t huge, but it was clearly visible and larger than the typical cosmetic dents you sometimes see that are already marked and deferred. I brought it to the captain’s attention, and he went down to inspect it himself. We both agreed it was something maintenance needed to look at.

Because Nashville is an outstation, contract maintenance was called out. That alone tends to slow things down, since they have to coordinate every step with company maintenance. We sat on the airplane for close to two hours while inspections and conversations went back and forth. Eventually, we were told we’d be switching aircraft—a different airplane was coming in from LaGuardia to take us back to JFK.

We gathered our things, moved gates, and started over. The new airplane had two small MEL items, one of which required a visual check of the forward cargo door to ensure it was properly secured, followed by a call to maintenance for corrective action. We did exactly that, documented everything, and finally pushed back. We received a flow time into JFK—not great, but workable.

While taxiing, ground instructed us to stop on a taxiway and wait for our flow time. Watching the clock, we decided to start the second engine in case we were released with little notice. Just as I was noting down taxi instructions from ground, an EICAS message popped up: ENGINE 2 NO DISPATCH.

That stopped everything.

We immediately told ground we needed to cancel taxi and troubleshoot. The QRH was simple—almost deceptively so. One line: DO NOT TAKE OFF. The captain got on the phone with maintenance, and I coordinated with operations to taxi back to the gate we had just left.

Back at the gate, maintenance came onboard and explained the troubleshooting process. The procedure required the aircraft to be fully powered down for ten minutes, start back up, and run the engine at the gate with the hope that the reset would clear the fault. The captain checked in with the flight attendants to see whether they wanted to keep passengers onboard during the process or deplane them, since sitting in a dark, unpowered aircraft for ten minutes isn’t exactly comfortable. Gate agents joined the conversation as well, concerned about passengers with connections at JFK.

Eventually, an announcement was made offering volunteers the option to deplane, receive hotel accommodations if needed, and be rebooked for the next day. Once that was sorted out, we shut everything down, waited ten minutes, powered back up, and started engine two again.

The same message came back.

Maintenance required us to attempt the procedure one more time, so we repeated the entire cycle: power down, wait ten minutes, power back up. While we were doing that, crew scheduling called to let us know that under Part 117, we needed to be wheels-up by 8:51 PM to remain legal. By this point, it was already around 8:30 PM. The clock was not on our side. We knew that even the second attempt was successful, we would've timed out.

The message didn't even disappear after the reset. It remained on the screen after powering up the second time before engine start. We started the engine at maintenance's directions, no luck. At this point, maintenance had exhausted their options, and shortly after, we got the final verdict that the flight was officially canceled.

Passengers deplaned, but we were instructed to remain onboard because the aircraft needed to be towed to a remote stand, and operations' procedure requires the flight crew to be onboard when towing a disabled airplane. None of us had ever done that before, so the captain verified with the pilot on duty that this was appropriate. Once confirmed, we complied and rode the airplane to the far stand.

Eventually, we were brought back to the terminal, walking past lines of passengers still waiting to be rebooked. At this point, crew scheduling assumed we’d overnight in Nashville and operate the same flight the next morning. But between the towing, the delays, and our original duty timeline, we wouldn’t get legal rest unless the show time was pushed back. After another round of calls, our report time was adjusted—barely enough to make it legal.

Then came the hotel confusion. Initially, we were told all four crew members would be at the same hotel. When the information finally populated in the system, the captain was assigned one hotel while the rest of us were sent to another. Crew scheduling called the captain and me separately to untangle the situation.

In the middle of all this, we were also pulled off our remaining legs for the next day. What was originally a multi-leg day out of JFK turned into just a single flight from Nashville to JFK, followed by a deadhead home to Boston. Not ideal—but at that point, fewer legs felt like a small mercy.

By the time I finally made it to the hotel, dinner was out of the question. Rest mattered more. Tomorrow would come quickly.

It was one of those days that remind you how much of this job lives outside the cockpit—maintenance coordination, passenger communication, legality calculations, and constant schedule changes. Exhausting, yes. But also oddly satisfying in its own way. We handled what came at us, stayed professional, and kept things moving as safely and cleanly as possible.

Hopefully, tomorrow will be quieter. But if not, at least I know we’ll handle it the same way.